Cryogenic supports

Our cryogenic supports at Ca.STIm. 2000 are special supports ideal for supporting pipes for low temperature operating systems, which therefore require special insulation, and include one or more layers of high-density polyurethane between the pipe and the actual support. These supports come in different types, for example saddle or collar. The insulating layer can be made up of different layers that can be included or released, depending on the supply requests on our client's specifications. A vapour barrier can also be used between the polyurethane layer and the actual support (a banding using layers of polyurethane and also materials capable of resisting temperatures they have to operate in) and also an additional aluminium coating.

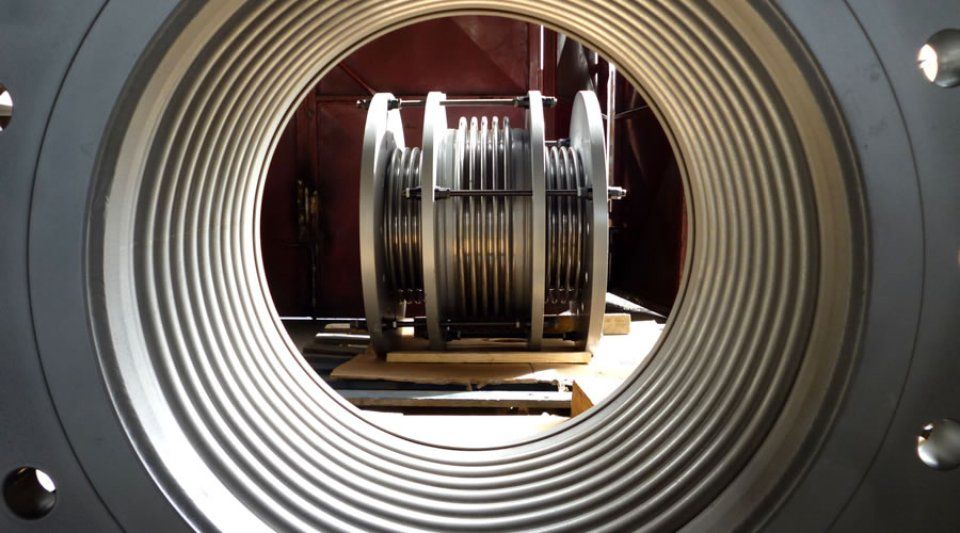

Expansion joints

Expansion joints are components that are used to help counterbalance the thermal expansion effects that occur on pipes or equipment.

Different types can be made, however, this will depend on the type of movement, thrust, temperature or pressure they have to support.

Essentially, there are three types of expansion joint:

Metal expansion joints which are usually designed according to the most accredited international standards such as EJMA (Expansion Joint Manufacturers Association), ASME VIII app. 26, PED.

Rubber expansion joints which are technically designed in the same way as the metal ones are - based on the proposal conditions, the bellows can be made of: EPDM, EPDM HT, Nitrile®, Neoprene®, Hypalon®, Viton®, Spec. Nitrile®,

Nitrile® White, Hypalon®, SBR, Viton®, Cloroprene, etc.

Fabric expansion joints are generally used in low pressure applications, where flexibility is needed, with significant strokes (axial, lateral, angular) acting simultaneously, in small spaces. The fabric expansion joint can be made of different materials (there are about 100 types of fabrics and felts made of glass, silica, ecological ceramics, metal nets, PTFE veneers and fluoropolymer laminated fabrics) and is strictly dependent on use.

For more info on our products